Sustainable product development

We create reliable and user-friendly products with as little environmental impact as possible.

We create reliable and user-friendly products with as little environmental impact as possible.

We create more sustainable products without compromising the reliability and the clinical performance that our products are known for. The embedded leaflet summarizes how we decrease the environmental footprint of our products – making them a more sustainable choice for our customers and for the planet.

Ecolabels are marks placed on product packaging to identify products that meet specific environmental performance criteria. The eco-labelling indicates that the products are “environmentally preferable”, helping thereby consumers make more sustainable choices when choosing between products. The "Swan" is the official Nordic ecolabel. As of 2022, it embosses our LoFric catheter range.

The Nordic Swan Ecolabel applies to: LoFric Elle, LoFric Origo, LoFric Sense, LoFric Hydro-Kit and LoFric Primo.

The best material to use in a catheter today is POBE, a polyolefin-based elastomer- that consists of carbon and hydrogen. POBE catheter material combines very good physical characteristics with an exceptional environmental performance. POBE has the lowest carbon footprint and environmental impact compared to PVC and polyurethane.1,2

When choosing a catheter made of POBE instead of PVC or polyurethane, every long-term user reduces the carbon footprint with up to 20kg CO2 per year.2

As of 2009, the tube material of our Lofric catheters are all made of POBE.

Finding more sustainable raw material sources to produce medical plastic devices is a game changer. By replacing fossil raw materials with bio-based raw materials, we reduce the end products’ environmental footprint without jeopardising the product’s clinical performance. In 2023, Wellspect successfully introduced bio-based raw materials into one of its products; a female urinary catheter with the name LoFric Elle.

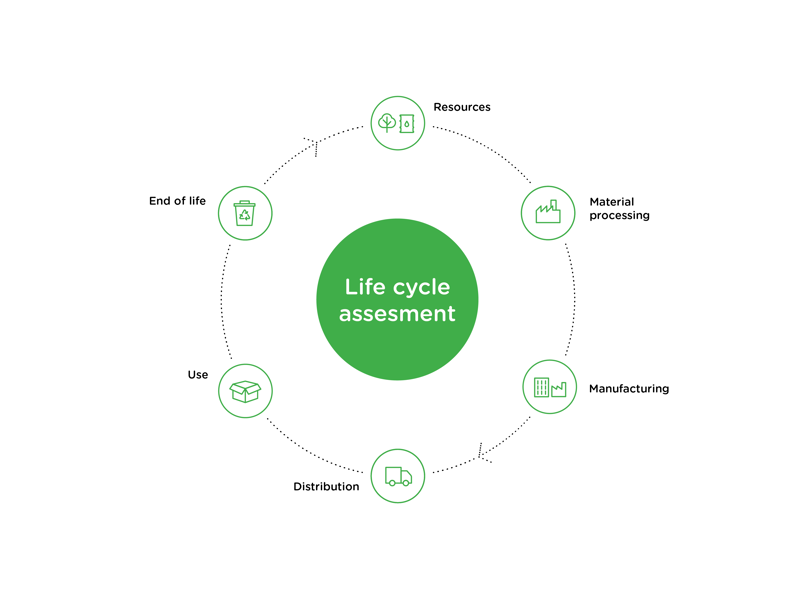

At Wellspect we use a Life Cycle Analysis (LCA) to identify which factors within the manufacturing of our products and consumables have the highest environmental impact. The LCA allows us to identify potential product improvements and areas where we can reduce the product's environmental footprint. The LCA process looks at all areas of the production process, from the sourcing of raw materials and manufacturing to distribution and eventually end of life.

Innovation is key to product superiority and to reduced environmental footprint. In 2020, we introduced a new coating process for our LoFric catheters. The new coating process uses 98% less water, cutting down substantially on water consumption. It also requires fewer chemicals due to the use of a different solvent which is the least harmful and most sustainable alternative available for the process. Both our coating process and our Urotonic Surface Technology have been thoroughly tested and validated according to the highest standards.